Students: Moran Keidar, Ms. Gelena Stepura

Former Student: Ron Scheuer

Supervisors: Dr. Valery Rosenband, Prof. Alon Gany

- Metal and Boron combustion.

- Nickel-coated Aluminium particles.

Oxidation, combustion and agglomeration phenomena of metal and boron particles in air and as additives in metallized solid propellants and fuels have been investigated extensively. Metal powders are used as fuel components in high energy combustion systems (air breathing) as well as in solid propellants, because of their high density and high heat of combustion. Some metal powders such as aluminum, magnesium boron, titanium, certain metal hydrides, as well as their mixtures, can be considered as candidate additives to solid rocket propellants.

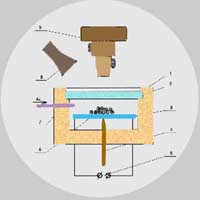

This work has investigated experimentally the microscopic behavior (ignition, combustion, agglomeration) of powders of these metals subjected to heating in inert and oxidative atmospheres. A windowed heated cell with direct access to microscopic observation was used for this research.

Particular attention has been given to the study of aluminum particles behavior, because of their widespread use in rocket propellants. It was observed that aluminum particles brought into close contact and maintained under appropriate heating conditions can agglomerate. Agglomeration appears as liquid bridges among resulting from molten metal flowing through cracks in the metal oxide layer surrounding each particle, and even as the coalescence of particles into larger size liquid drops.

References

Natan, B. and Gany, A., Combustion Characteristics of a Boron-Fueled Solid Fuel Ramjet with Aft-Burner, J. of Propulsion and Power, Vol. 9, No. 4, July-Aug. 1993, pp. 694-701.

Gany, A., Combustion of Boron-Containing Fuels in Solid Fuel Ramjets, in: Combustion of Boron-Based Solid Propellants and Solid Fuels, K.K. Kuo and R. Pein, editors, Begell House and CRC Press, Boca Raton, FL, 1993, pp. 91-112.

Rosenband, V., Gany, A. and Timnat, Y.M., A Model for Low Temperature Ignition of Magnesium Particles,Combustion Science and Technology, Vol. 105, 1995, pp. 279-294.

Rosenband, V., Schneebaum, Y. and Gany, A., Some Thermodynamic Aspects Related to Steel Reactive Erosion,Wear, Vol. 221, 1998, pp. 109-115.

Rosenband, V. and Gany, A., A Microscopic and Analytic Study of Aluminum Particles Agglomeration, Combustion Science and Technology, Vol. 166, 2001, pp. 91-108.

Rosenband, V. and Gany, A., Thermo-Mechanical Aspects of Hot-Gas Corrosion of Metals, Research Trends Journal, Trends in Corrosion Research (Special Issue), Vol. 3, 2004, pp. 1-22.

Shafirovich, E., Bocanegra, P.E., Chanveau, C., Gokalp, I., Goldshleger, U., Rosenband, V. and Gany, A., Ignition of Single Nickel-Coated Aluminum Particles, Proceedings of the Combustion Institute, Vol. 30, 2005, pp. 2055-2062.

Rosenband, V., Torkar, M. and Gany, A., Self-Propagating High-Temperature Synthesis of Complex Nitrides of Intermetallics, Intermetallics, Vol. 14, No. 5, 2006, pp. 551-559.

Rosenband, V. and Gany, A., Agglomeration and Ignition of Aluminum Particles Coated by Nickel, accepted for publication in Advancement in Energetic Materials and Chemical Propulsion, J. Rivera and K.K. Kuo, editors, Begell House.

Gany, A., Energy and Thermodynamic Aspects of Boron-Containing Solid Fuel Combustion, International Conference on Combustion and Detonation (Zeldovich Memorial II), Moscow, Russia, Aug. 30-Sept. 3, 2004 (Plenary Lecture).

Scheuer, R. and Gany, A., Thermodynamic Effect of Boron Combustion in Ramjet Propulsion, 17th International Symposium on Air Breathing Engines (ISABE), Munich, Germany, Sept. 4-9, 2005.

Gany, A., Comprehensive Consideration of Boron Combustion in Airbreathing Propulsion, AIAA Paper 2006-4567, 42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Sacramento, CA, USA, July 9-12, 2006.

Nickel-Coated Aluminum Particles

Student: Yinon Yavor

Supervisors: Dr Valery Rosenband and Prof Alon Gany

Dramatic Results of Enhanced Ignition and Reduced Agglomeration

A novel method developed in house produces aluminum powders with controlled weight fraction and thickness of the nickel coating.

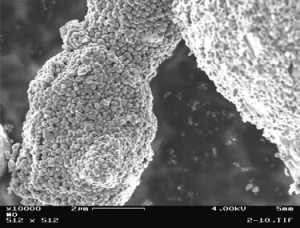

Samples of aluminum particles coated with a thin nickel layer were prepared and characterized. The as-received Al particle surface is relatively smooth, whereas the surface of the nickel-coated Al particles seems to be covered by numerous small (100-200 nm) bonded nickel particles.

|

|

|

|

To study ignitability characteristics of aluminum particles coated by nickel as compared with regular aluminum particles, aluminum powder was placed on an electrically heated canthal tape in air. The powder temperature was measured by a thermocouple embedded in the powder. It was found that a regular aluminum powder does not ignite in these conditions even at temperatures as high as 12000C, whereas the powder coated by nickel (5 wt%) does ignite (at about 80000C). In that case, ignition is promoted for several reasons. One of them is the exothermic reaction between aluminum and nickel, enhancing the heating rate of the particle.

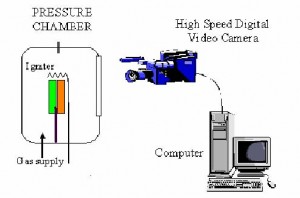

The effect of nickel-coating of the aluminum particles on the burning of aluminized solid propellants has been investigated. Based on previous research it was believed that shortening the ignition time of the aluminum particles would imply reduced agglomeration. Combustion of two adjacent HTPB-based propellant strands containing 20µm AP and 15% of 6µm Al particles was photographed by a high-speed video camera at a frame-rate of 1000 pictures per second. Large agglomerates are observed for the propellant containing regular (uncoated) aluminum. Higher particle flux of smaller agglomerates is observed for the propellant containing nickel-coated aluminum. The photos taken show that nickel-coated aluminum particles produce substantially smaller agglomerates than regular aluminum. The existence of smaller agglomerates can also be indirectly implied from the higher burning particle flux. The experiment supports the physical argument, that the coating of aluminum particles by nickel reduces agglomeration.

|

|

References

Yavor, Y. and Gany A., “Combustion of Solid Propellant Containing Regular or Nickel-Coated Aluminum”, Poster No. 20, 22nd Annual Symposium of the Israeli Section of the Combustion Institute, Tel Aviv, December 21, 2006.

Shafirovich, E., Bocanegra, P.E., Chanveau, C., Gokalp, I., Goldshleger, U., Rosenband, V. and Gany, A., “Ignition of Single Nickel-Coated Aluminum Particles”, Proceeding of the Combustion Institute, Vol. 30, 2005, pp.2055-2062.

Hahma, A., Gany, A. and Palovuori, K., “Combustion of Activated Aluminum”, Combustion and Flame, Vol. 145, No. 3, May 2006, pp. 464-480.

Rosenband, V. and Gany, A., “Agglomeration and Ignition of Aluminum Particles Coated by Nickel”, Advancement in Energetic Materials and Chemical Propulsion, J. Rivera and K.K. Kuo, editors, Begell House, New York,2007, pp. 141-149.